A3 thinking is a structured approach to practical problem solving and continuous improvement. It is based upon the internationally-recognised PDCA (Plan-Do-Check-Act) cycle and famously utilised by the Toyota Motor Corporation.

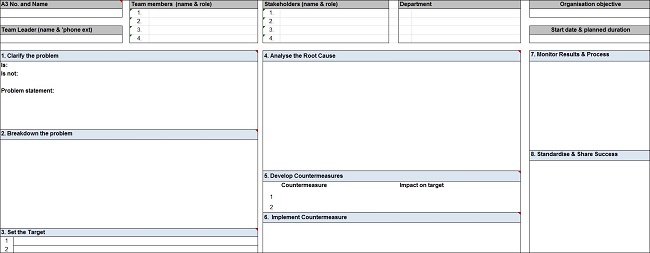

There are numerous templates for A3 problem solving - here is one typical example:

- Clarify the problem

- Break down the problem

- Set a target

- Analyse the root cause of the problem

- Develop countermeasures

- Implement countermeasures

- Monitor results and process

- Standardise and share success

Today, A3 Thinking is frequently employed as a team-based problem solving tactic within quick thinking organisations. The name 'A3 Thinking' is derived from the A3 worksheet that practitioners of this system use to tackle problems - FAST.

Image from Wikipedia - full size version here

The main advantage of A3 problem solving is the way in which it drives towards a comprehensive understanding of the problem at hand and helps the user(s) to identify the best available countermeasures. Using the A3 approach is also a great way to demonstrate continuous improvement and corrective action if you are certified to ISO 9001.

If you would like to implement a structured problem solving / continuous improvement system within your organisation, please contact NPT Management Systems to discuss your requirements. Our experienced consultants have helped numerous companies from a broad variety of business sectors to solve problems fast whilst eliminating waste and significantly improving productivity.

All too often, attempts to achieve real improvement within an organisation fail to get results because the managers are aiming for a one-off fix instead of for sustained growth over time. Continuous improvement should be the goal, and this can be attained via a solid continuous business improvement programme.

Of course, these programmes are only effective if everyone in your company understands how to work with the programme and implement it in every area of the business. Fortunately, we at NPT Management Systems don't just help you to plan your continuous improvement programme - we can also provide in-depth continuous improvement training sessions for your staff to ensure that they have full understanding of (and confidence in) the new system. With our training, your employees will be capable of:

- Identifying business process problems

- Resolving process problems quickly

- Assuming a leadership role when solving process problems

We will also make sure that everyone is well-versed in such important improvement tools as process mapping, cause and effect diagrams, and pareto diagrams.

For more information about our continuous improvement training service, please contact NPT Management Systems today.

We do more than just implement ISO management systems!

When you're looking to improve and grow your business, it's easy to focus on one process at a time while ignoring the bigger picture of your company as a whole. Improving processes in isolation may not yield the results you want; instead, we recommend that you implement a continuous improvement programme that is linked to the strategic direction of your business.

ISO 9001 certification isn't the only service that we offer here at NPT Management Systems. We can also help you to design and implement a comprehensive business improvement programme that will simplify and perfect all of your processes while synchronising your efforts with the overall direction of the company.

And that's not all: we also deliver exercise-focused training sessions to help you and your employees to get more from your continuous improvement programme. We can provide a wide range of training topics - here are a few examples of what we can provide:

- Identifying process problems and waste

- Root cause analysis

- Process mapping

- Cause and effect diagrams

- Change management tools and techniques

Click here to learn more about our continual improvement services, or contact us now to find out more about how we can help your business.